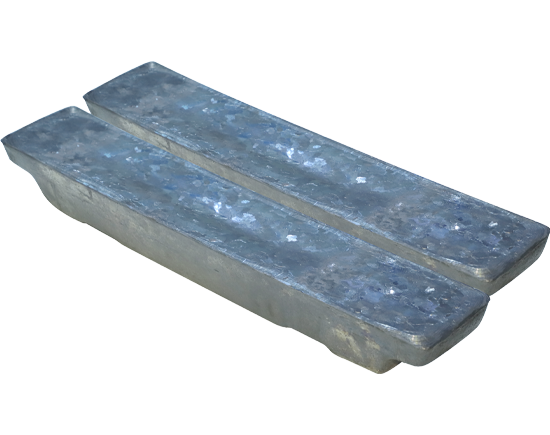

Under the jurisdiction of the company, there are 11 main gold mines, 1 copper mine and 1 pycnite mine, among which Liaoshang gold mine is a large mine, and the other gold mines are all medium-sized mines. The total reserves are 30.31 million tons, the gold metal volume is about 103 tons, and the approved production capacity of mining and selection is more than 1.2 million tons/year.

-

Liaoshang gold mine is located in Guanshui Town, Muping DistrictThe mining area is about 1.6 square kilometers, with reserves of 20.31 million tons, gold metal volume of about 75 tons, production scale of 900,000 tons/year, service life of more than 20 years;

-

Muping Lasigou gold mine is located in Shuidao Town, Muping DistrictThe mining area covers an area of approximately 1.8 square kilometers. The retained reserves exceed 1 million tons, with the gold metal content being over 3 tons. The production scale is 120,000 tons per year. The retained reserves of other gold mines can all meet the mining capacity for more than 5 years.

The reserves of other gold mines all meet the mining capacity of more than 5 years. Lasigou Gold Mine and Liaoshang Gold Mine are both secondary safety standardization enterprises in Shandong Province. Lasigou gold mine is a provincial green mine in Shandong Province.