-

First GenerationGravity separation method and amalgamation method

First GenerationGravity separation method and amalgamation method -

Second GenerationDirect cyanide method

Second GenerationDirect cyanide method -

The Third GenerationOne-stage roasting cyanide gold extraction

The Third GenerationOne-stage roasting cyanide gold extraction -

The Fourth GenerationPre-oxidization-cyaniding method

The Fourth GenerationPre-oxidization-cyaniding method -

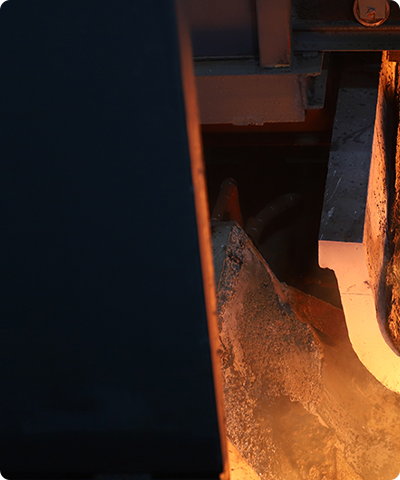

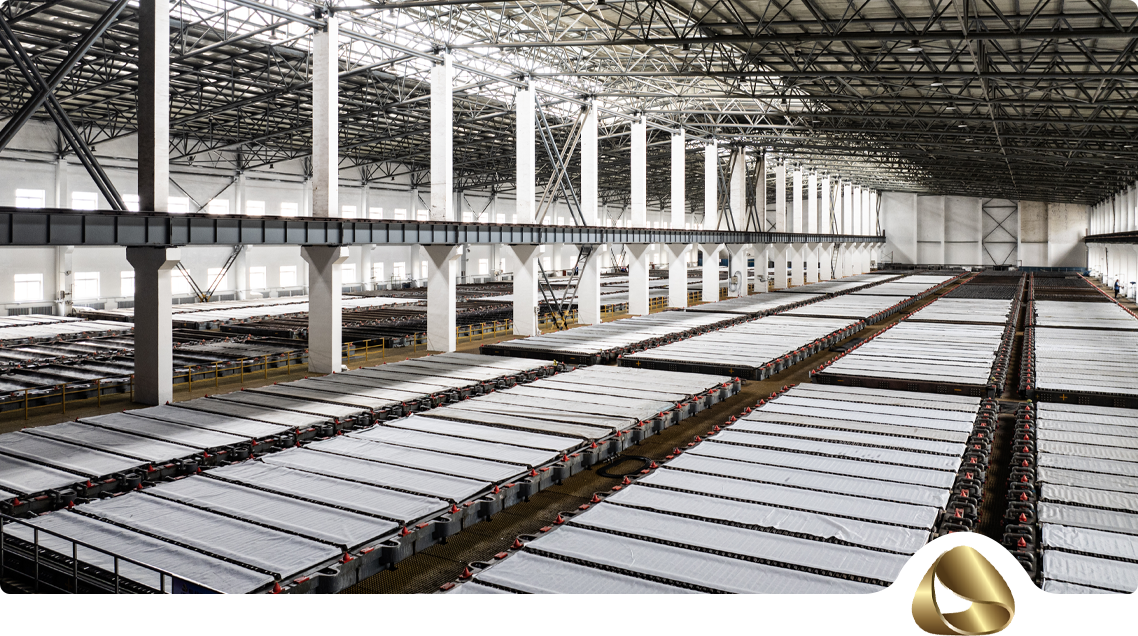

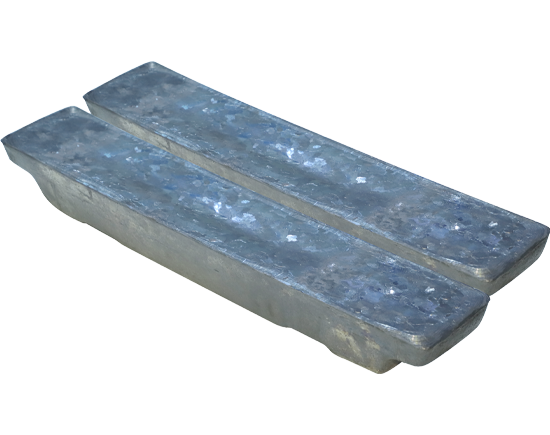

The Fifth GenerationCyanide-free pyrometallurgical processss

The Fifth GenerationCyanide-free pyrometallurgical processss

The first four generations all belong to the traditional hydrometallurgical process, which has the advantages of less capital occupation and short metal realization cycle, but also has problems such as hazardous cyanide slag waste, high ore quality requirements, low metal recovery rate and difficult extraction of associated elements, resulting in the waste of mineral resources. The fifth generation of cyanide-free pyrometallurgical technology system developed by the company has cured hazardous cyanide slag from the source, and has strong raw material adaptability, as well as significant advantages of multi-element extraction, low comprehensive energy consumption and high metal yield. Based on this, the company has won 2 second prizes of National Science and Technology Progress, 10 first prizes of provincial and ministerial science and technology progress, national green factory, national energy efficiency "leader" and many other honors.